In the complex world of maritime engineering, ship design is a meticulous, multi-phase process that blends innovation, technical precision, and regulatory compliance. For stakeholders in the shipping industry, understanding these stages is critical to ensuring safety, efficiency, and cost-effectiveness. As a leading marine engineering consultant, we leverage cutting-edge research, industry standards, and decades of expertise to deliver optimized vessel designs. In this article, we break down the six core stages of ship design, supported by insights from journals, authoritative texts, and case studies.

Source: Royal United Services Institute of Nova Scotia. (n.d.). Royal United Services Institute of Nova Scotia. https://rusi-ns.ca/

1. Conceptual Design: Laying the Foundation

The conceptual design phase establishes the vessel’s purpose, feasibility, and initial specifications. Stakeholders collaborate to define requirements such as cargo capacity, speed, range, and operational environment. Key parameters like hull form, propulsion type, and tonnage are explored through preliminary calculations and simulations.

According to Ship Design and Construction (Lamb, 2003), this stage prioritizes trade-off analyses to balance performance, cost, and environmental impact. For example, a bulk carrier’s hull geometry might be optimized using computational fluid dynamics (CFD) to minimize resistance, as noted in a 2021 Journal of Marine Science and Application study.

2. Preliminary Design: Refining the Vision

Once the concept is approved, engineers develop detailed hydrodynamic and structural models. Stability analyses, weight distribution, and powering requirements are validated against classification society rules (e.g., Lloyd’s Register, ABS).

A 2019 study in Ocean Engineering highlights the role of parametric design tools in this phase, enabling rapid iteration of hull forms and machinery systems. For instance, the choice between diesel-electric or LNG-powered propulsion hinges on lifecycle cost assessments and emissions regulations like IMO Tier III.

3. Contract Design: Finalizing Specifications

The contract design phase translates requirements into legally binding documents, including general arrangements, machinery layouts, and compliance plans. Regulatory adherence to SOLAS, MARPOL, and the International Load Line Convention is rigorously verified.

Per the International Maritime Organization (IMO) guidelines, this stage also addresses safety systems, fire protection, and escape routes. Advanced tools like Building Information Modeling (BIM) streamline collaboration between shipyards, owners, and marine engineering consultants, as outlined in a 2022 Ship Technology Research paper.

4. Detailed Design: Engineering Precision

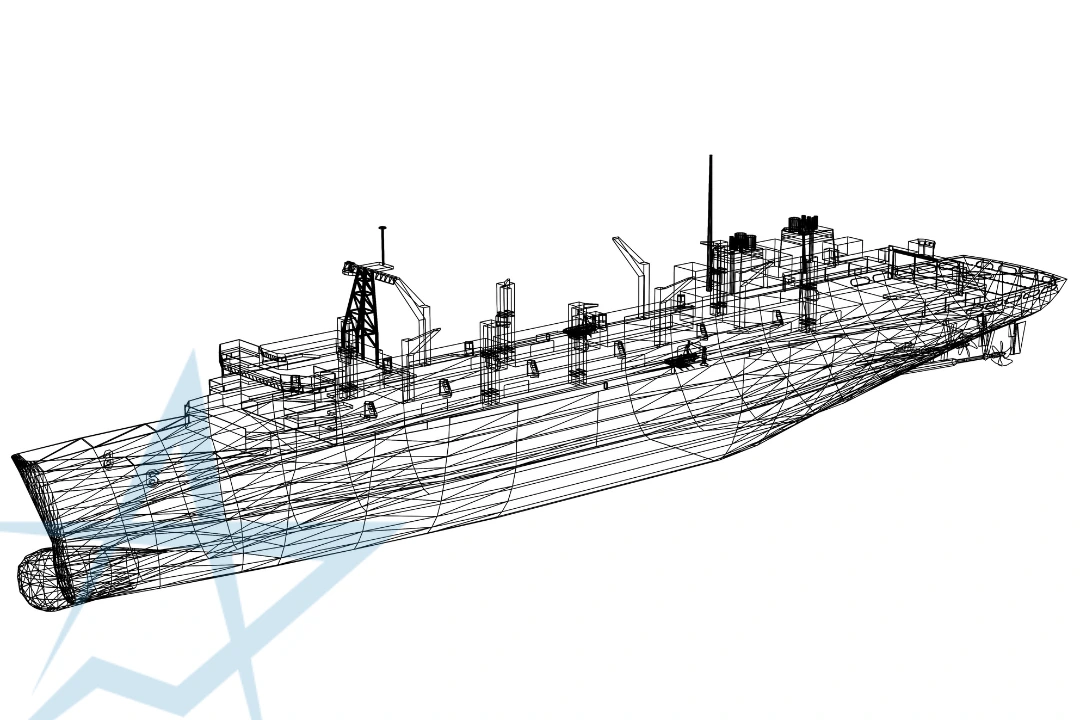

Here, every component is specified down to the bolt. Structural drawings, piping diagrams, and electrical systems are drafted using CAD software. Finite Element Analysis (FEA) ensures the hull withstands dynamic loads, per the American Bureau of Shipping (ABS) Steel Vessel Rules.

Recent advancements, such as 3D-printed prototypes and digital twins, are revolutionizing this stage. A 2023 Journal of Marine Engineering study emphasizes how virtual testing reduces errors and accelerates approvals.

5. Construction Support: From Blueprint to Reality

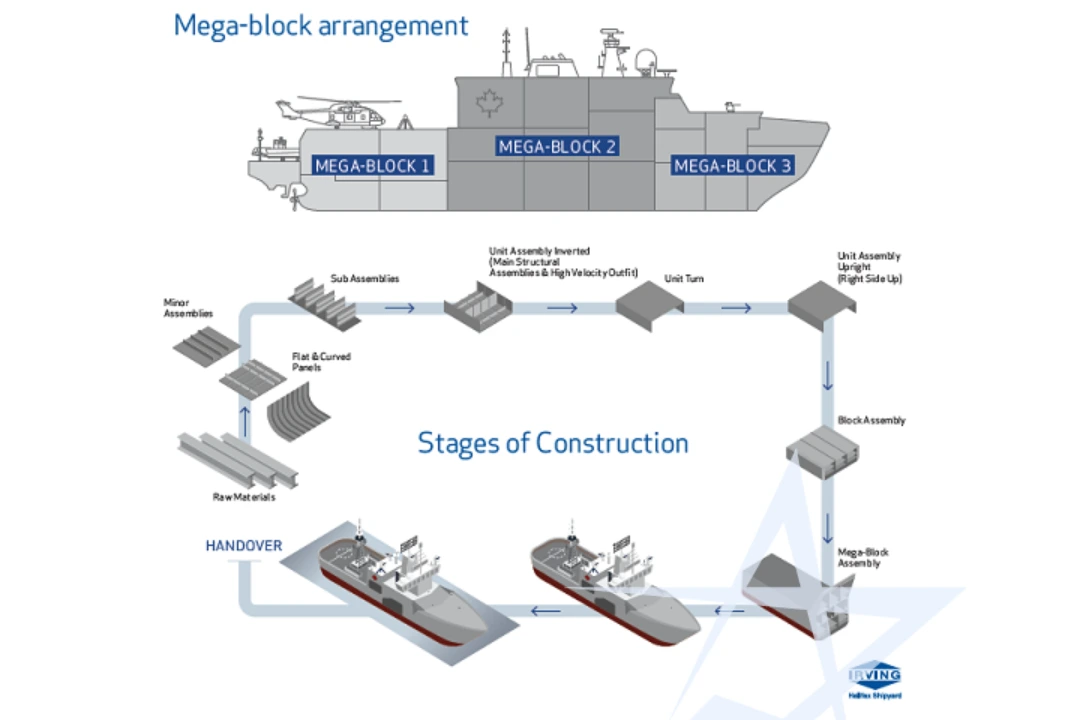

During shipbuilding, engineers provide on-site support to resolve fabrication challenges. Quality control checks, weld inspections, and machinery installation align with class society standards (e.g., DNV GL).

Modular construction techniques, as discussed in Ship Construction (Eyres, 2012), improve efficiency by assembling pre-fabricated blocks. Real-time monitoring via IoT sensors ensures adherence to tolerances, minimizing rework.

6. Post-Delivery: Trials and Optimization

After launch, sea trials validate speed, maneuverability, and system performance. Data from these tests, as per the Society of Naval Architects and Marine Engineers (SNAME), informs final adjustments.

Post-delivery, continuous monitoring via IoT and AI-driven analytics helps optimize fuel consumption and maintenance schedules. A 2023 Marine Policy report underscores how such strategies enhance ROI and reduce carbon footprints.

Ship design is a symphony of engineering rigor, creativity, and strategic planning. By partnering with a seasoned marine engineering consultant, stakeholders can ensure their vessels meet today’s challenges while anticipating tomorrow’s demands. From conceptual sketches to post-delivery analytics, every stage is an opportunity to innovate and excel.

References

1. Lamb, T. (2003). Ship Design and Construction. SNAME.

2. International Maritime Organization (IMO). SOLAS Consolidated Edition.

3. Journal of Marine Science and Application. (2021). “Hydrodynamic Optimization in Conceptual Ship Design.”

4. ABS. (2023). Rules for Building and Classing Steel Vessels.

5. Eyres, D. J. (2012). Ship Construction. Butterworth-Heinemann.